Smart manufacturing, also known as Industry 4.0, represents a transformative change in the manufacturing sector, driven by the integration of advanced technologies and data analytics.

Currently, it is revolutionizing the way we conceive and carry out production processes around the world. In this article, I want to delve into the field of smart manufacturing, the benefits, future trends…

The Smart Manufacturing revolution

Smart manufacturing is a production approach that uses digitalization and automation to improve efficiency in manufacturing processes.

In other words, manufacturing combines information technology and communication technology with machines and manufacturing processes to generate more efficient processes.

Think of traditional manufacturing as taking a road trip with a map and smart manufacturing as having a GPS that guides us along the best routes. This type of manufacturing has evolved from manual labor and basic machinery to a world where machines communicate with each other, analyze data and make decisions much faster.

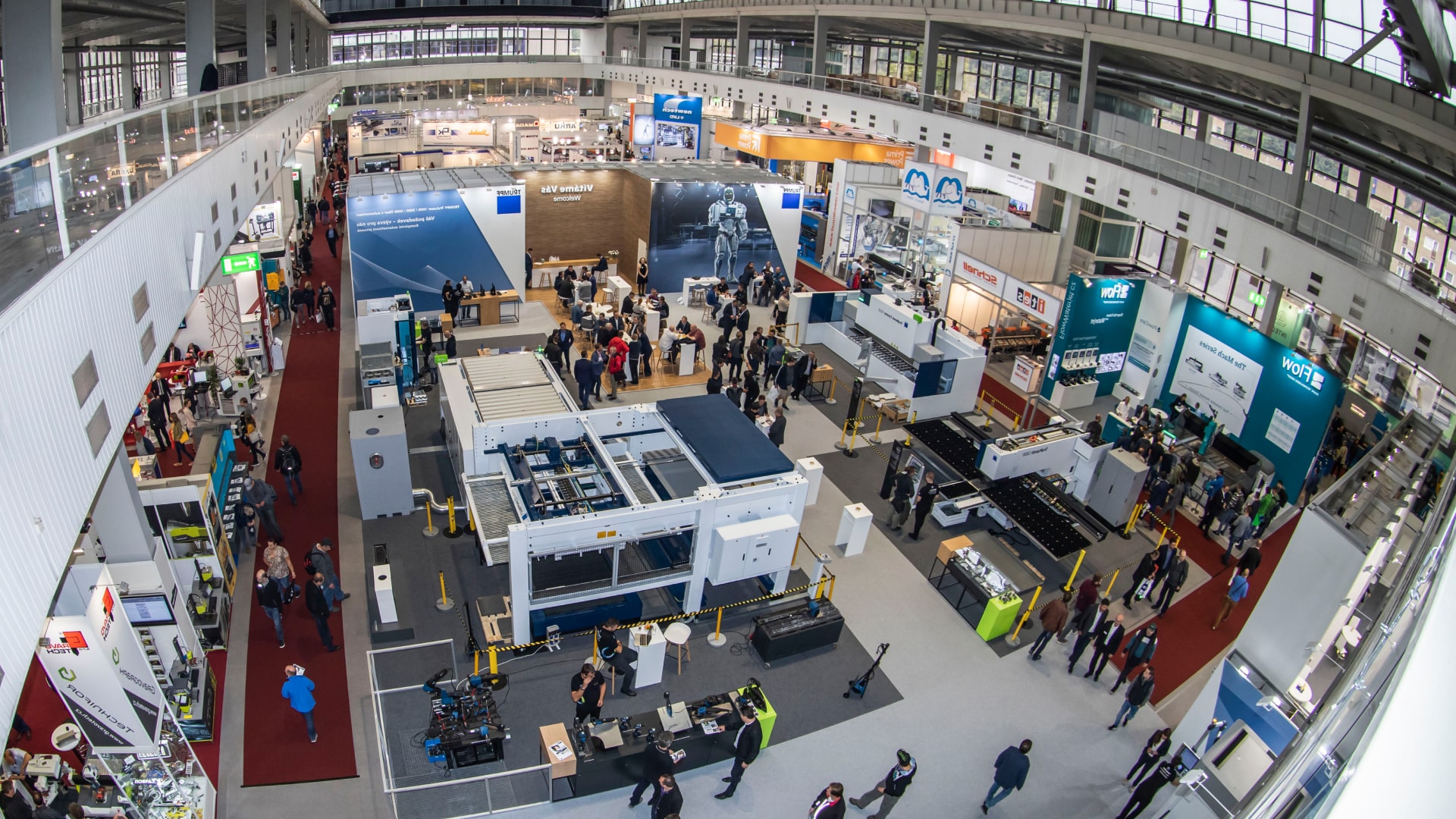

The impact of Smart Manufacturing in Industry

Smart manufacturing has become a fundamental pillar in today’s industry. Being used by large factories around the world to generate great benefits, including:

- Improved efficiency: It allows companies to optimize their operations, reduce waste and improve efficiency.

- Custom production: It allows for customized mass production, meaning that products can be customized to meet specific customer needs without incurring additional costs.

- Quality improvement: Through smart manufacturing, errors can be detected and corrected in real time, resulting in higher quality products.

- Greater knowledge of industrial processes: The data collected and analyzed can provide deeper insight into industrial processes, enabling smarter decision making.

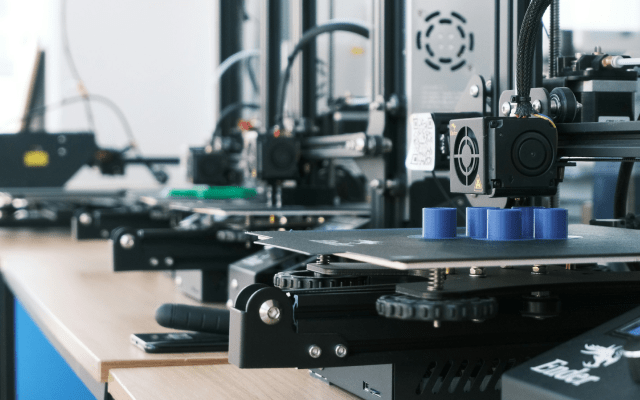

RTM Pro in industrial manufacturing

To generate greater efficiency, real-time data collection and analysis is necessary, allowing companies to make more informed and productive decisions.

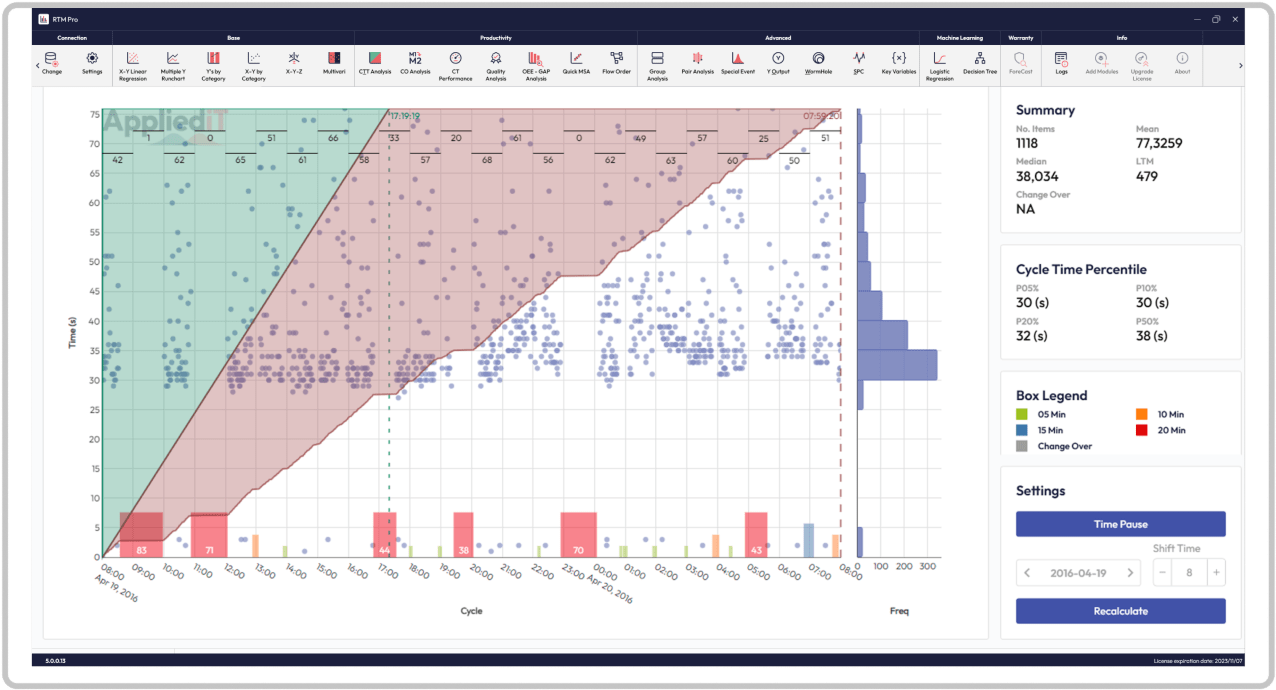

At AppliediT, we are aware of its importance, which is why we provide our solutions for those companies that seek to stand out in Industry 4.0, through our leading software for data analytics, RTM Pro.

RTM Pro is capable of improving companies’ decision making through real-time data analytics, providing easier and faster problem resolution in industrial environments than with other data analysis platforms.

Large companies such as Airbus, Continental, Vitesco, Dräxlmaier… work daily with RTM Pro to generate data analytics, collect valuable information, visualize opportunities for improvement… But above all, to increase the efficiency of their factories, reduce costs, and capitalize on your data.

Transformation in production

Data analytics has revolutionized the way companies operate and produce goods and services. In production, data analytics can have a significant impact in several areas:

- Supply chain optimization: Data analytics helps companies forecast product demand, optimize inventory, and improve efficiency. This results in a reduction in costs and an increase in customer satisfaction.

- Product quality improvement: Through it, patterns and trends can be identified that may indicate quality problems.

- Operating efficiency: It reveals inefficiencies in production processes that can be difficult to detect with the naked eye. Thanks to this, productivity and profitability are improved.

- Development of new products: Customer data can provide valuable insights into customer preferences and needs.

- Data-driven decision making: Decisions can be more informed by hard data. This can result in more accurate and effective decisions.

Conclusion

The smart manufacturing revolution is changing the way manufacturing companies operate and redefining the boundaries of what is possible in the industry. With the ability to optimize production, improve efficiency and foster innovation, this technology continues to transform the way factories operate.

By harnessing the power of advanced technologies, companies improve quality, reduce costs and accelerate production time. At AppliediT we continue to grow and generate great innovations, offering solutions such as RTM Pro, our real-time data analytics software that continues to drive Industry 4.0.

It is important to understand the impact and value of smart manufacturing, as it is not only transforming the industry, but is also opening a new path for us in production and innovation. Are you ready to stand out in Industry 4.0? Contact our experts.

Share this post