In today’s competitive business landscape, operational efficiency is paramount for long-term success. OPEX (Operational Excellence) solutions are designed to optimize processes, reduce costs, and improve quality, all while maintaining a focus on customer satisfaction.

This article provides a comprehensive approach to implementing OPEX solutions, leveraging insights from AppliediT’s Ramp-up Method to maximize efficiency and achieve operational excellence.

The Importance of Maximizing Efficiency

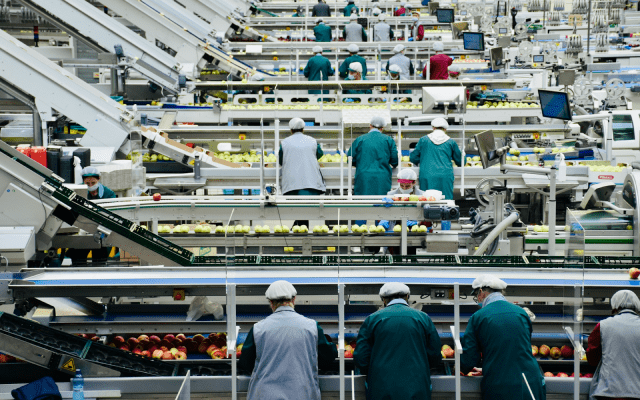

Understanding the importance of maximizing efficiency is crucial for companies aiming to remain competitive, increase profitability, and meet customer demand. Efficiency directly impacts costs by streamlining processes, reducing waste, and minimizing energy consumption. When production is trouble-free and optimal, the need for overtime, machine downtime, and raw material waste is reduced.

Optimized workflows lead to faster production cycles, enabling manufacturers to produce more in less time without additional resources. Standardized processes ensure consistent, high-quality products, reducing the chances of defects and errors. Efficiency improvements lead to significant reductions in material waste, energy consumption, and unused capacity, enhancing profit margins.

Step-by-Step Guide to Implementing OPEX Solutions

Initial Evaluation and Diagnosis

The first step involves a thorough assessment of all critical processes within your organization. This includes evaluating the current efficiency of each process, considering time, resources, and materials used. Detecting areas generating large waste and eliminating activities that do not add value to production is essential. Benchmarking against industry best practices helps identify areas for improvement and set realistic goals.

Definition of Objectives and KPIs

Defining clear and achievable objectives aligned with your company’s vision and mission is crucial. Focus on identifying areas for cost reduction without compromising product or service quality. Establish higher quality standards and implement methods to achieve them. Set clear goals for each department, creating workflows and adopting advanced technologies.

Implementing Improvements

Designing a customized OPEX strategy tailored to your company’s needs involves selecting an appropriate methodology. AppliediT offers expert advice to identify the most effective methodologies. Developing a detailed plan with schedules, resources, and responsibilities ensures synchronization with objectives and capabilities.

Implement OPEX Solutions

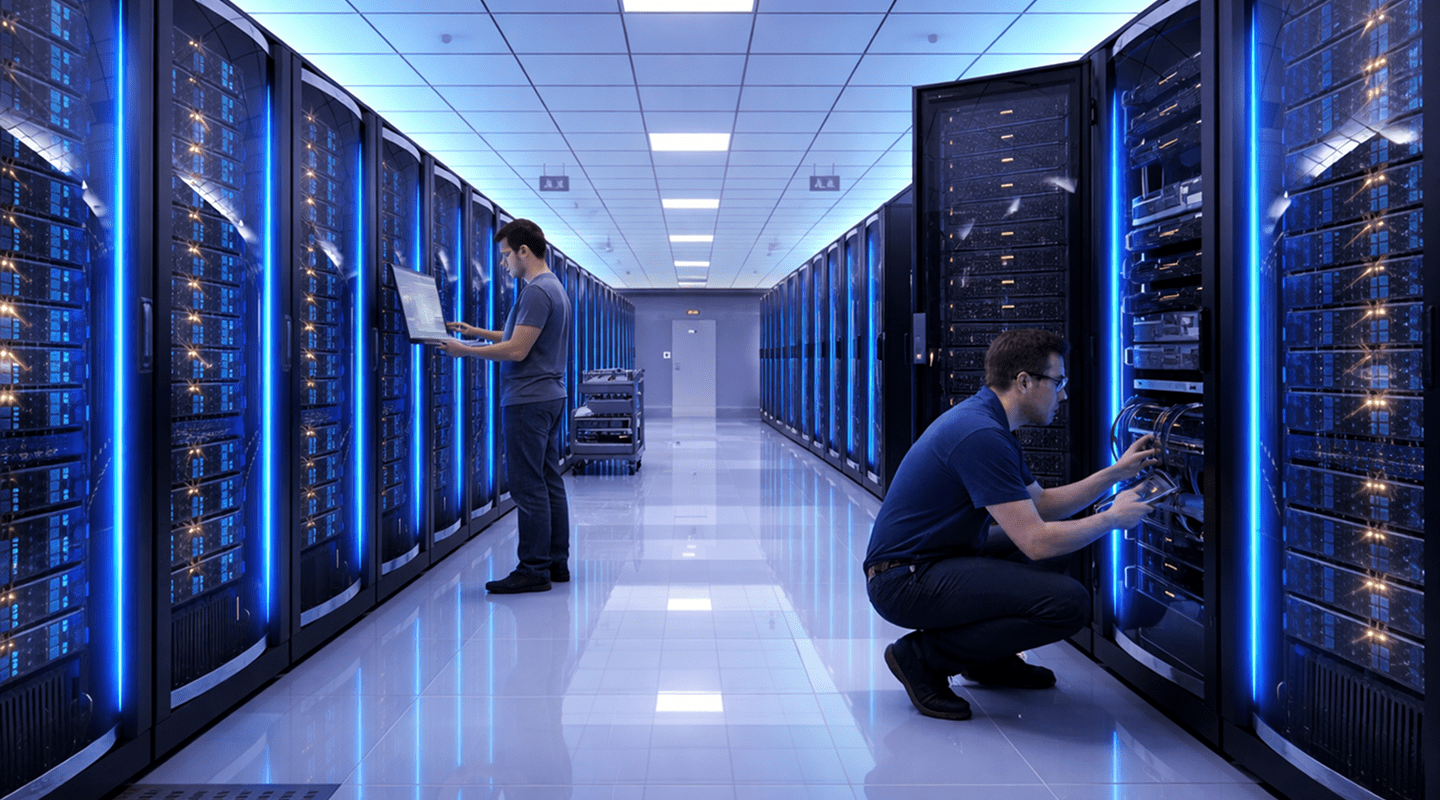

This crucial phase involves starting with pilot projects to test OPEX solutions in a controlled environment. AppliediT’s RTM Pro software allows real-time performance tracking and optimization. Continuous monitoring of progress and making necessary adjustments is vital. Keeping all stakeholders informed about progress and results, providing regular training in OPEX methodologies and relevant tools, and fostering a culture of continuous improvement empowers employees to suggest and implement improvements.

Monitoring and Adjustment

Ensuring the continued success of OPEX initiatives requires measuring and analyzing results. AppliediT’s team can assist with establishing key performance indicators reflecting initial goals. Using RTM Pro to assess the impact of OPEX solutions and create actionable insights is beneficial. Collecting and analyzing feedback helps identify areas for improvement and innovation.

Review and Continuous Improvement

Operational excellence is a continuous journey. Maintaining and improving results involves conducting regular audits of processes and OPEX strategies. Staying flexible and prepared to adapt to market fluctuations and technological advances is necessary. Fostering a culture of continuous innovation, offering workshops and programs to inspire employees to propose improvements, is essential.

Insights from AppliediT’s Ramp-up Method

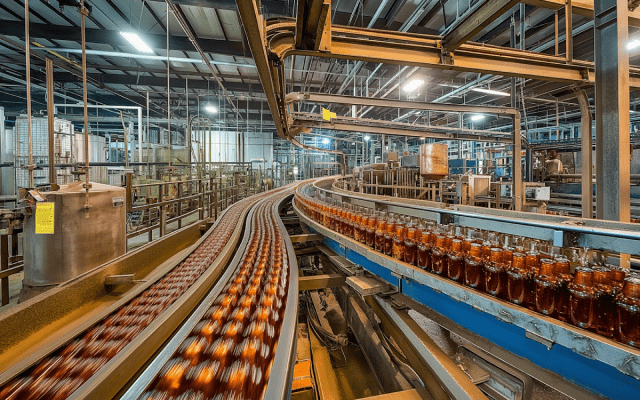

The Ramp-up Method by AppliediT focuses on mastering Overall Equipment Effectiveness (OEE) improvement in manufacturing. It emphasizes a structured approach to minimize delays, accelerate stabilization, and ensure a faster path to full performance. AppliediT has a history of successful OPEX projects across various locations, including the USA, China, Germany, and more. Key achievements include scrap rate reduction, problem-solving, and ramp-up of high-value motor systems.

The phased ramp-up approach includes verifying process and product readiness, tracking machine readiness, and resolving readiness gaps in the pre-ramp-up phase. The ramp-up phase involves validating processes, conducting sample production, establishing KPIs, and solving complex problems. Performance optimization focuses on resolving chronic issues, optimizing takt time, and ensuring a smooth production flow. Uplift efficiency aims to achieve target cycle time, stabilize production flow, and optimize maintenance activities.

Key tools and methods include RTM Pro software for real-time data analysis and tracking OEE progress, DOIT-AIT methodology for complex problem resolution, and data analytics for assessing OEE potential and optimizing ramp-up phases. Strategic ramp-up benefits include achieving 75% OEE 2-3 months sooner, cutting 8-25 weeks from the ramp-up process, engaging customer teams in a task force manner, ensuring quick improvements and high motivation, and fostering a culture of continuous improvement.

Conclusion

Implementing OPEX solutions requires commitment, strategic planning, and a mindset focused on continuous improvement. By following this step-by-step guide and leveraging AppliediT’s Ramp-up Method, your organization can maximize operational efficiency, significantly reduce costs, and substantially improve customer satisfaction.

Remember, operational excellence is not a destination but a continuous process of improvement and innovation. With the right tools, methodologies, and expert support, your organization can transform challenges into opportunities and build a more efficient and competitive future.

Would you like to know how we can implement this in your company? Contact us and we will advise you without obligation.

Share this post