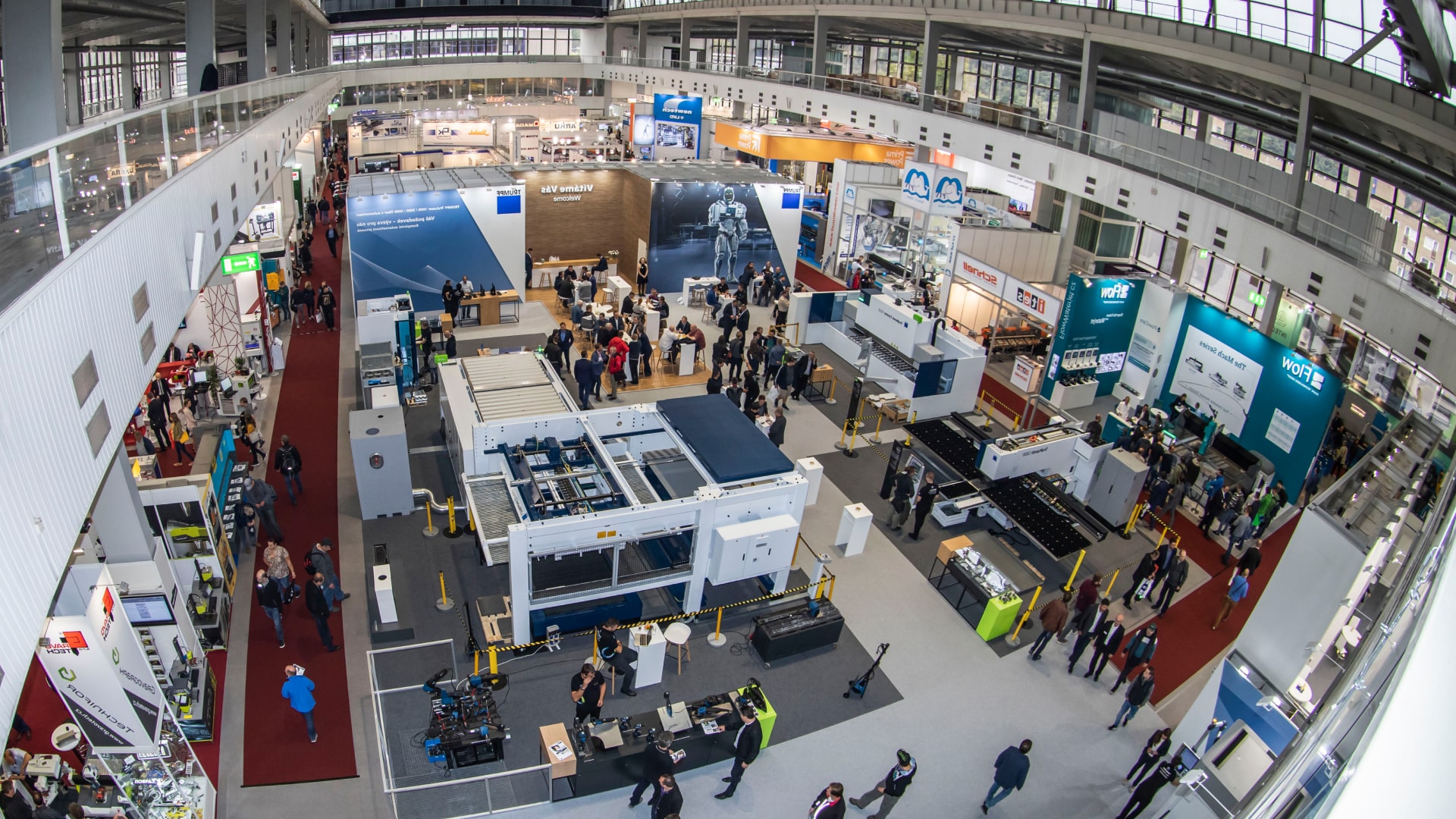

Do you know how IoT and data analytics are transforming the industryThe manufacturing industry is undergoing a major transformation thanks to the advances in IoT and data analytics. IoT refers to the network of physical devices, sensors, and software that can collect and exchange data over the internet. Data analytics refers to the process of analyzing large amounts of data to extract useful insights and patterns.

IoT and data analytics enable smart manufacturing, which is the use of intelligent systems and processes to optimize production and operations. Smart manufacturing can improve efficiency, quality, safety, sustainability, and profitability in the industry. Here are some of the benefits and challenges of smart manufacturing.

Benefits of Smart Manufacturing

- Increased productivity: IoT and data analytics can help monitor and control the production process in real time, reducing downtime, waste, and errors. They can also enable predictive maintenance, which can prevent equipment failures and extend their lifespan.

- Enhanced quality: IoT and data analytics can help ensure consistent quality standards across different products, batches, and locations. They can also enable quality control and testing, which can detect defects and anomalies early and reduce rework and recalls.

- Improved safety: IoT and data analytics can help improve worker safety by monitoring environmental conditions, detecting hazards, and alerting workers and managers. They can also enable remote operation and automation, which can reduce human exposure to dangerous tasks and environments.

- Reduced environmental impact: IoT and data analytics can help reduce energy consumption, emissions, and waste in the manufacturing process. They can also enable circular economy practices, such as reuse, recycling, and remanufacturing of materials and products.

- Increased competitiveness: IoT and data analytics can help manufacturers gain a competitive edge by enabling innovation, customization, and differentiation of products and services. They can also enable collaboration and integration across the supply chain, enhancing customer satisfaction and loyalty.

Challenges of Smart Manufacturing

- High cost: IoT and data analytics require significant investment in hardware, software, connectivity, security, and skills. The return on investment may not be immediate or clear, especially for small and medium-sized enterprises (SMEs).

- Cybersecurity risks: IoT and data analytics increase the exposure of manufacturers to cyberattacks, which can compromise data integrity, privacy, and availability. Cyberattacks can also cause physical damage to equipment and products, endangering workers and customers.

- Regulatory compliance: IoT and data analytics involve collecting, storing, processing, and sharing large amounts of data across different jurisdictions.

- Manufacturers need to comply with various laws and regulations regarding data protection, privacy, ownership, and usage.

- Organizational change: IoT and data analytics require a shift in organizational culture, structure, and processes. Manufacturers need to adopt a data-driven mindset, foster collaboration across departments and partners, and empower workers with new skills and roles.

How IoT and data analytics are transforming the industry: Conclusions

IoT and data analytics are transforming the manufacturing industry by enabling smart manufacturing. Smart manufacturing can bring many benefits to manufacturers in terms of efficiency, quality, safety, sustainability, and profitability. However, smart manufacturing also poses many challenges in terms of cost, cybersecurity risks, regulatory compliance and organizational change. Manufacturers need to overcome these challenges by investing wisely implementing robust security measures following best practices and embracing change.

Share this post