The manufacturing industry is closing a 2025 marked by unprecedented technological acceleration. Plants have made strides in digitalization, automation, and sustainability as they try to adapt to an increasingly demanding global context. However, the real challenge has not been adopting technology, but turning data and improvement initiatives into sustainable operational results.

With everything learned this year, the sector is preparing for a 2026 where the transformation will be even more profound. A year in which data analytics, operational excellence (OPEX) and industrial platforms will play a key role in moving from experimentation to execution.

This analysis summarises what 2025 has marked, what will continue to drive the evolution of the sector and what new trends are beginning to take shape for 2026, with a clear focus on how to bring them to reality in the plant.

Trends that have been consolidated in 2025

Digitalization and smart manufacturing

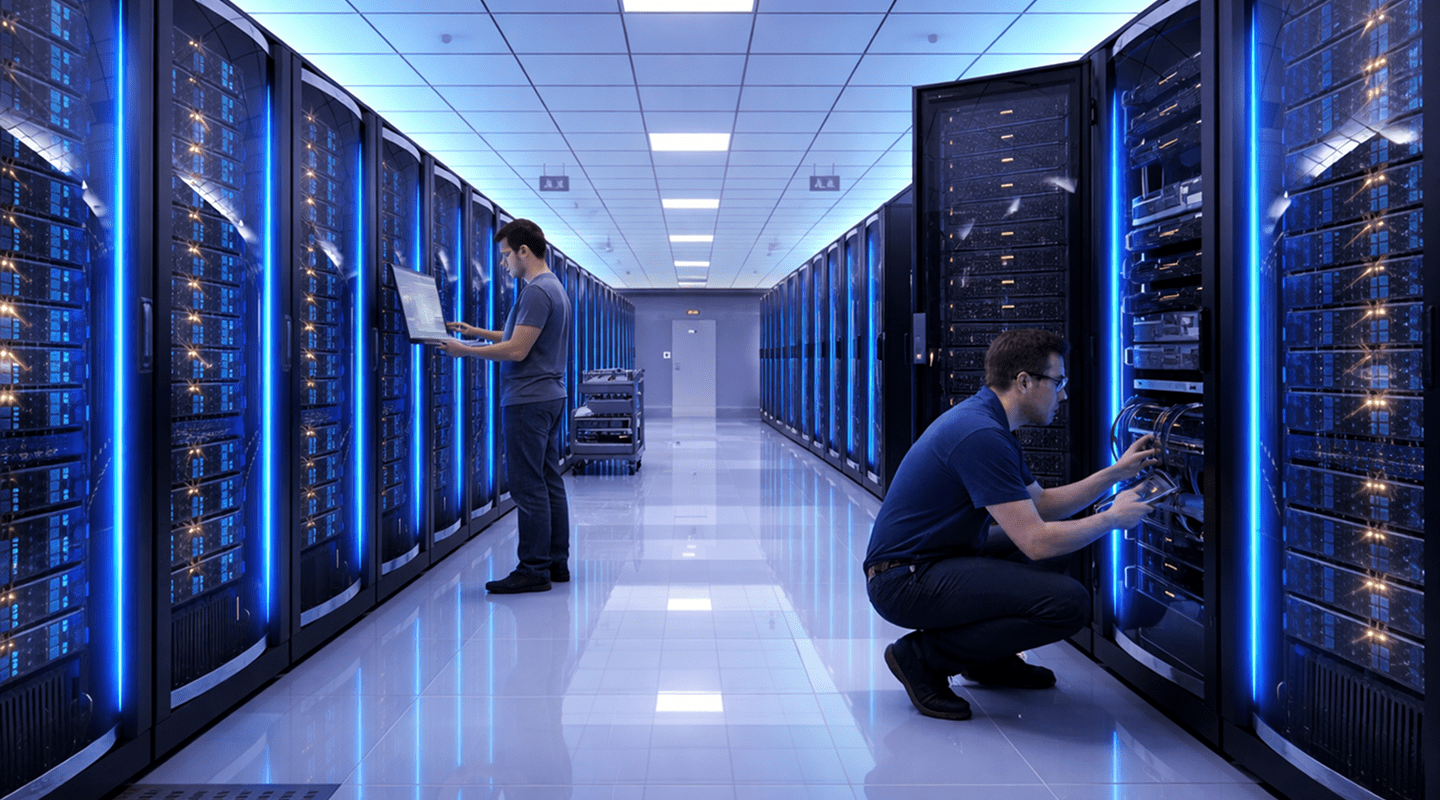

2025 has been a key year for the real adoption of connected technologies: industrial IoT, unified data platforms and advanced analytics systems. Factories have gone from measuring to understanding and acting on real-time data, reducing variability and improving process control.

The difference has been made by those organizations capable of integrating data from multiple sources (production, quality, maintenance) into a common vision of operational performance. In this context, performance management platforms such as RTM Pro make it possible to consolidate critical information, analyze deviations and prioritize improvement actions in a structured way, laying the foundations for sustainable continuous improvement.

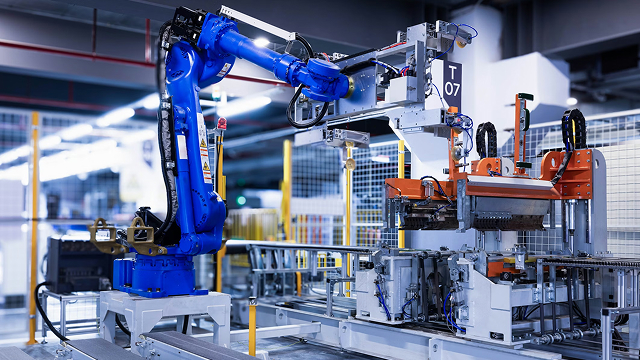

Flexible automation and collaborative robotics

Collaborative robotics has become widespread in sectors where it previously seemed unfeasible. AGVs and AMRs have become common internal logistics assets.

The key to 2025 has not only been to automate, but to integrate these technologies within well-defined processes, aligned with clear productivity, quality and safety objectives.

Artificial intelligence applied to operations

By 2025, AI will no longer be a pilot to become a stable part of many plants: failure prediction, automatic defect detection, dynamic parameter adjustment or statistical process control assisted by advanced algorithms.

The dominant concept has been clear: anticipating rather than reacting. But the real value appears when these capabilities are integrated into an operational management system that allows insights to be converted into actions.

New profiles and evolution of talent

Plants have had to adapt roles and processes in the face of a continuous deficit of technical profiles. There is a growing need for professionals capable of interpreting data, managing connected systems, and working with analytical tools that support daily decision-making.

Technology begins to act as a multiplier of operational knowledge, reducing dependence on individual expertise.

Trends that will continue to drive the industry in 2026

Increased operational resilience and focus on cybersecurity

Increasing interconnection requires strengthening the protection of industrial infrastructures. In 2026 we will see more investment in robust architectures that guarantee operational continuity and data reliability, a prerequisite for any strategy based on advanced analytics.

Open ecosystems and composable platforms

The trend of 2025 will continue to expand in 2026: adoption of interoperable systems that make it easier to integrate new equipment, data or modules without complex projects.

This approach allows you to build scalable industrial platforms where data analytics and performance management can evolve without redoing the architecture every few years.

Moving towards hyperautomation

AI, advanced analytics, and process automation will continue to converge in 2026 to create processes that are continuously optimized. Hyperautomation does not seek to eliminate people, but to free up operational time and reduce variability, supporting continuous improvement based on real data.

People-centric operations

The industry is moving towards environments where the operator works with more intuitive tools: simplified interfaces, guided processes and intelligent data-driven support. By 2026, the human-in-the-loop approach will be reinforced, where technology supports decision-making without replacing operational judgment.

Emerging trends that will shape the leap towards 2026

Microfactories and distributed production models

The demand for flexibility and proximity to the customer will mean that in 2026 this modular and scalable model will be explored more. For it to work, it will be key to have common data and analytics models that allow the performance of multiple facilities to be managed in a coherent way.

Augmented and virtual reality as operational tools

XR will go from being an interesting innovation to an everyday tool for training, maintenance and standardization of processes, accelerating knowledge transfer and reducing operational errors.

IA autónoma (Agentic AI)

The transition to systems capable of making operational decisions without constant supervision is being developed: energy optimization, automatic adjustments or identification of root causes. In 2026 we will start to see real applications, especially when these capabilities are integrated into analytics and performance management platforms.

Dynamic Digital Twins

Digital Twins evolve into living models connected to real plant data. In 2026 we will see digital twins capable of predicting behaviors, optimizing processes, and validating complete operational scenarios before executing changes.

How to land these trends in plant reality

All of these trends converge on one common point: the need to turn data and technology into effective operational decisions. To do this, organizations need a structured approach that connects analytics, processes, and people.

Data analytics applied to operational performance make it possible to identify losses, understand their causes and prioritize actions with a real impact on OPEX. Platforms such as RTM Pro facilitate this transition by offering an integrated view of performance, aligned with production, quality and reliability objectives.

This approach is especially critical in (pre)ramp-up and ramp-up phases, where variability is high and early decisions determine future performance. Having reliable data, clear indicators, and monitoring mechanisms from the earliest stages allows you to accelerate stabilization, reduce deviations, and achieve target performance in less time.

The combination of advanced analytics, OPEX models and rigorous ramp-up management thus becomes a differentiating factor for new lines, plants or industrial launches.

Conclusion: 2026, from data to operational excellence

2025 has marked a turning point. Manufacturing is no longer experimenting with technologies – it’s running, scaling, and transforming entire operations. By 2026, competitive advantage will come from combining data analytics, industry platforms, and operational excellence models to turn insights into sustainable decisions and outcomes.

Companies that know how to integrate these trends within a structured approach to OPEX and operational performance management will be the ones to lead the change in the coming years.

At AppliediT we accompany industrial organizations on this path, connecting data, processes and people to transform operational complexity into measurable and sustainable results from the first phases of ramp-up to stable operation.

Share this post