In the intricate landscape of manufacturing, where efficiency reigns supreme, lies the cornerstone of operational excellence: Overall Equipment Effectiveness (OEE).

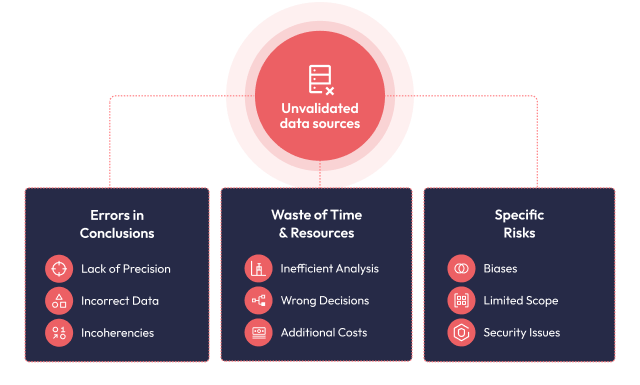

As the most critical Key Performance Indicator (KPI) in every manufacturing company, OEE holds the power to illuminate operational performance, yet its calculation often veers into divergent paths, influenced by the nuances of individual processes and unvalidated data sources.

Challenges in calculations

The variability in OEE calculation arises from the imperative to delineate internal losses from external ones, coupled with the inherent uncertainties in performance metrics and the pervasive inaccuracies in availability assessments. The traditional approach of multiplying Performance, Availability, and Quality to derive OEE struggles to contend with these challenges, risking misinterpretation and misallocation of resources.

Methodology in AppliediT

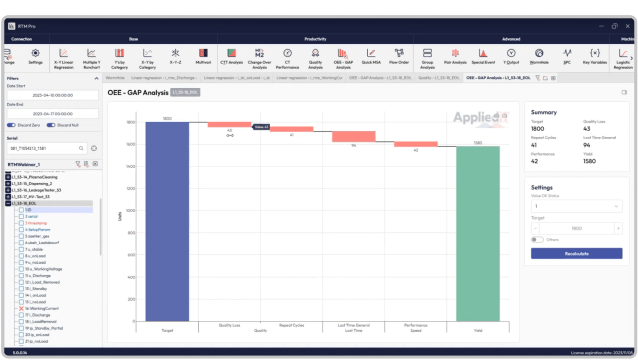

At AppliedIT, we recognize the perils of miscalculating OEE and have devised a pioneering approach to mitigate this risk. Our methodology commences with a meticulous examination of discrete parts, utilizing the AppliedIT GAP analysis. This ensures unparalleled accuracy in OEE calculation, transcending the limitations of conventional methodologies and laying the groundwork for informed decision-making and targeted interventions.

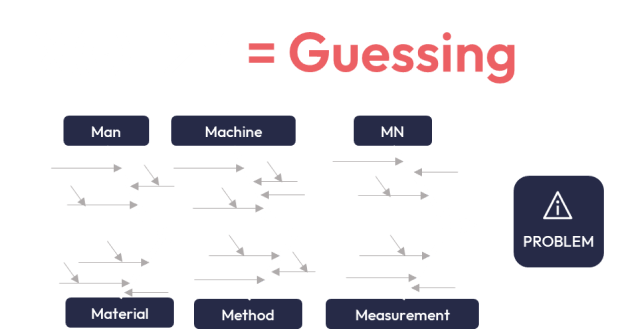

Let’s see the comparison of two paradigms. First of all, we find “Cause ->Problem”, which would be the push principle. In this process we ask ourselves the questions “What is happening? How does this work?”

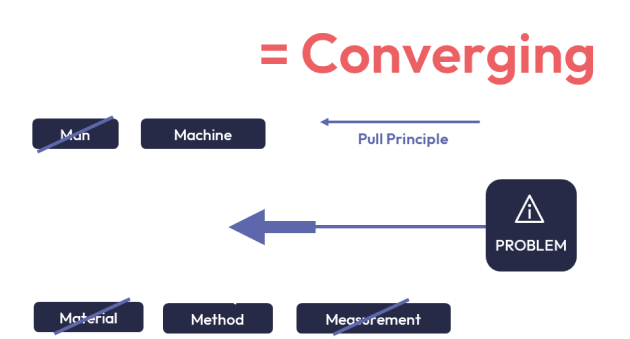

Secondly, we find the “Problem>Cause”. This process demonstrates the LEAN problem-solving approach, in which we ask the question “What is different?”

Our Y-to-X approach, depicted graphically, serves as the cornerstone of our methodology, guiding organizations towards a comprehensive understanding of OEE dynamics. Through the utilization of the AppliedIT gap analysis tool, we streamline the process, unraveling the complexities of OEE with simplicity and clarity.

Operational Optimization

By establishing trust in the primary KPI, organizations can unlock the gateway to operational optimization. With a reliable foundation in OEE, they can direct their focus towards what truly matters in their processes, driving continuous improvement and sustainable growth.

Join us at AppliedIT as we navigate the multifaceted terrain of OEE, illuminating its different shades to empower organizations towards manufacturing excellence and operational resilience.

Together, let us embark on a journey of transformation, fueled by the undeniable power of OEE.

Conclusion

OEE is a key indicator for operational excellence, but its calculation can be very complex. With our methodology, we overcome the limitations of traditional methods, providing unprecedented precision in the calculation of OEE.

With AppliediT GAP analysis and Y-to-X graphical representation, companies can achieve great benefits.

- Optimize production and reduce costs.

- Implement a continuous improvement cycle.

- Make strategic decisions based on reliable data.

- Foster a culture of excellence around OEE.

Are you ready to embark on the journey to operational excellence? Contact us through contact@applieditweb.com and discover how you can transform your business with our solutions and methodologies.

Share this post