In the era of Industry 4.0, connectivity is key to success. Maintaining a connected industrial ecosystem allows companies to share their data in their own factory, collaborate more efficiently and make decisions with more precision.

In this post, we want to talk about the top 5 reasons why you should connect your industrial ecosystem and how you could do it easily with the help of our solutions.

Optimization of Operational Efficiency

One of the most compelling reasons to connect your industrial system is the significant improvement in operational efficiency. Operational efficiency refers to an organization’s ability to minimize waste and maximize the use of its resources.

Connecting your industrial ecosystem can lead to greater efficiency by enabling real-time process monitoring and control. With live updates and alerts, you can make quick decisions to optimize performance.

Additionally, automated workflows and processes can streamline operations, reduce downtime, and increase productivity.

Improved data visibility and analysis

In today’s digital age, data visibility and analytics have become crucial components to the success of any industrial ecosystem.

Centralized data collection and integration allow you to gain a comprehensive view of your operations, making it easy to identify trends and patterns.

With better data visibility, you can: Improve operational efficiency, reduce downtime, optimize performance, make better decisions…

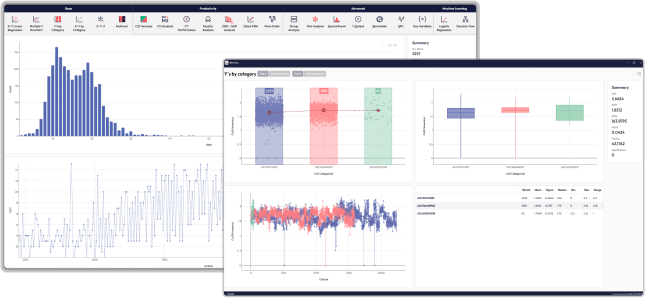

RTM Pro our data analytics software, allows our customers to have a complete view of all the information behind their data, thereby improving efficiency and reducing problems in manufacturing environments.

Optimized collaboration and communication

In an industrial environment, effective collaboration between teams and departments is crucial to the success of a project. Connecting your industrial ecosystem allows you to improve different aspects:

- Information flow is improved

By connecting your industrial ecosystem, you can facilitate a constant, real-time flow of information. This allows all team members to have access to the most up-to-date data, helping to make informed decisions quickly. - Greater transparency

A connected ecosystem provides complete visibility into all operations. This not only helps identify and resolve issues quickly, but also fosters a more transparent and trustworthy work environment. - Efficient coordination

With the help of digital tools and collaboration platforms, teams can coordinate more efficiently. This reduces downtime and improves overall productivity. - Quick response to changes

In a dynamic industrial environment, conditions can change rapidly. A connected ecosystem allows teams to respond to these changes in a timely manner, thereby minimizing any negative impact on production. - Innovation driven by collaboration

By connecting your industrial ecosystem, you can foster a collaborative work environment that drives innovation. Teams can share ideas and solutions, which can lead to significant improvements and advancements.

Connecting your industrial ecosystem fosters optimized collaboration and communication between teams and departments.

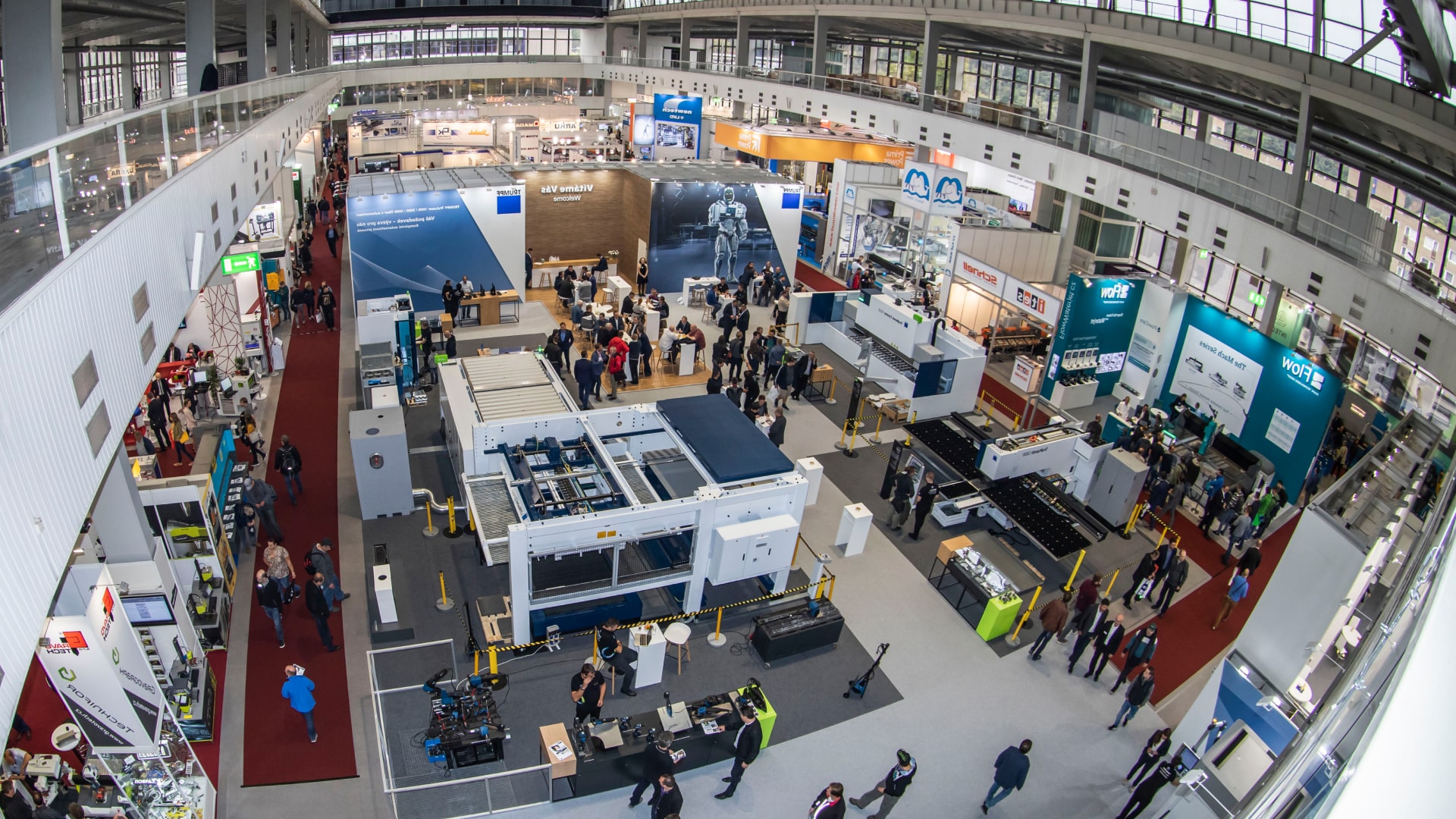

Greater innovation and agility

In an increasingly competitive and fast-paced world, innovation and agility are crucial to staying ahead. Connecting your industrial ecosystem can be a powerful catalyst for both.

By connecting your industry ecosystem, you can drive greater innovation and agility within your organization.

Rapid prototyping and testing becomes more accessible, allowing you to experiment with new ideas and technologies. With the ability to quickly adapt to market changes, you’ll be able to stay ahead of the competition and take advantage of growth opportunities.

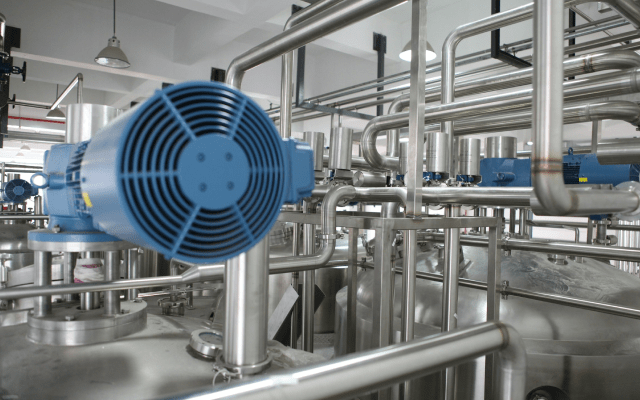

Reduced downtime and waste

Connecting your operations can generate significant cost savings and resource optimization.

By streamlining communication and data sharing between machines and systems, you can identify inefficiencies, reduce waste, and make smarter decisions that will ultimately save you money.

You can reduce downtime and waste through real-time monitoring, predictive maintenance, production optimization, process automation, continuous improvement…

Conclusion

In short, connecting your industrial ecosystem is not just an option, but a necessity in today’s world. The advantages are countless: from process optimization to improving energy efficiency, to the ability to make decisions based on real-time data.

The digitalization of the industry is a path that we must all follow to remain competitive and relevant in the market. So, if you haven’t started connecting your industrial ecosystem yet, now is the time.

Remember, opportunities are not something that comes to us, they are something we create. Go ahead, take the leap into the future of the industry with all our solutions!

Share this post